Biology-First

Manufacturing

Progress in medicine and biological research increasingly depends on access to large quantities of high-quality human cells—expanded, differentiated, and engineered cells with biological fidelity.

Harton’s Solid State Bioprocessing (SSB) technology provides a new foundation for human cell manufacturing, delivered through an automated, GMP-ready platform: HT-1.

Harton Preserves

True Biology

with Scalable 3D Culture

In the body, cells do not exist in isolation. Yet most manufacturing systems rely on suspension or 2D environments that strip away the structure, microforces, and localized signaling that shape cell identity in vivo. The result is processes that are fragile, variable, and difficult to scale—producing cells that are often scarce, expensive, or inconsistent.

Harton’s 3D culture technology is designed to preserve true biology by recreating the microenvironments cells need to remain functional, enabling reproducible human cell manufacturing from research and development to large-scale clinical production.

Biology Responds

to Structure

Cells sense and respond to their environment. 3D structure shapes growth, migration, differentiation, and functional state.

Quality Emerges

from Context

Cell potency and phenotype are not intrinsic. Tissue-like microenvironments supply essential biological cues.

3D Culture Scales Naturally

Cells grow densely in tissues. Perfused 3D culture supports high-density growth beyond the limits of suspension and 2D culture.

Take a Look Inside

Take a Look Inside

Integrated 3D Biology

& Closed-System

Cell Processing

A Structured Environment that Mirrors In Vivo Biology

The SSB contains a tunable 3D matrix that recreates the physical and biochemical context cells require to grow, interact, and mature naturally.

Tissue-Like Structure

The SSB provides a 3D architecture that supports natural cellular morphology and spatial organization. By restoring cell–cell and cell–matrix interactions, it promotes consistent expression of cellular phenotype.

Controlled Microforces

The 3D matrix is tunable. By adjusting stiffness, porosity, and elasticity, the SSB can be optimized for diverse cell types and workflows to support the desired morphology and functional state.

Enhanced Signaling

The SSB presents biochemical cues in a localized and uniform way, improving the efficiency and consistency of signaling across cells. This enables stage-specific programming and reduces reliance on high cytokine and growth factor dosing.

In vivo-like Perfusion

Perfusion continuously delivers nutrients and removes waste without disruptive media exchanges, maintaining stability over long culture timelines. The SSB perfusion architecture recreates natural fluidic forces to enable dense 3D cell growth.

Billions of Cells in a

Compact, Closed Cartridge

The Solid-State Bioprocessor (SSB) is operationalized within a single-use, GMP-ready cartridge that unites perfused 3D culture, integrated cell processing, genetic engineering, and embedded sensing. Together, these elements enable clinical- and commercial-scale cell production while preserving the biological conditions required for consistent identity, phenotype, and function.

Scalable, Fully-Integrated, and GMP-Ready Consumable

A single HT-1 cartridge supports multiple SSB scales at high cell density for up to multi-billion cell outputs within a closed, compact format.

The same cartridge integrates upstream and downstream unit operations, including cell processing and genetic engineering steps, enabling end-to-end workflows in one consumable.

.jpg)

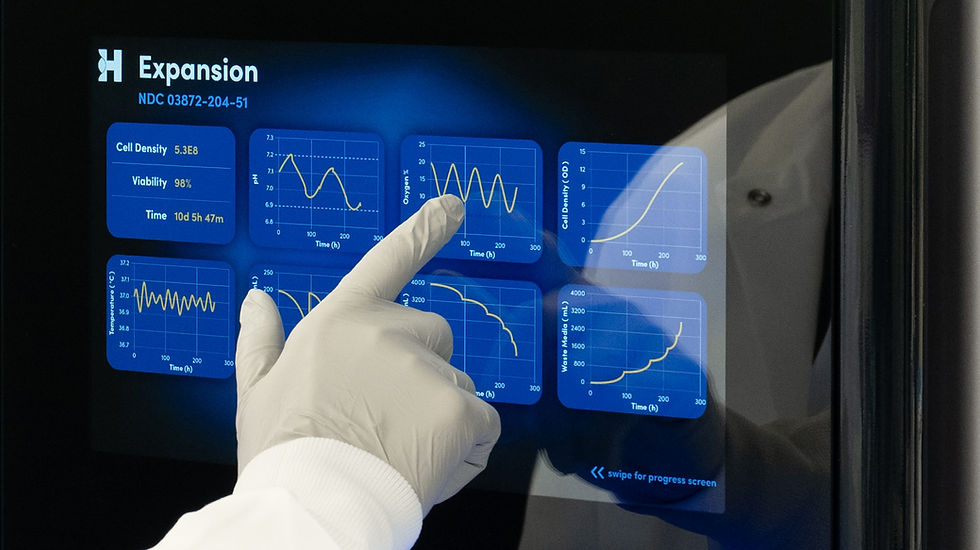

Advanced Real-Time Sensors for

Closed-Loop Biological Control

Embedded optical and environmental sensors monitor critical process parameters in real time, including oxygenation, temperature, pH, viable biomass, key analytes, and cytometry.

HT-1 uses these measurements to maintain stable biological setpoints and execute adaptive programs that respond to cell state.

Built for Consistency, Quality & Scale

HT-1 delivers biologically superior cell outputs with operational simplicity — improving quality, cost, and speed from research through GMP manufacturing.

Quality & Function

-

Increased expression of functional markers

-

Higher viability across long culture timelines

-

Improved consistency in phenotype and output quality

Efficiency

-

10× higher density in the same footprint

-

Lower cytokine, media, and reagent consumption

-

Reduce failure modes from contamination and handling

Scalability

-

One platform from R&D through GMP

-

Consistent performance across sites and operators